Standard gaskets of all sizes & shape: Size: from ½” to 60”

Pressure Class: LBS 150, 300, 400, 600, 900, 1500 and 2500

Conforming to :

- Chevron standards

- ASME B16.20, B16.47A & B

Tested for:

- Minimum shear, pressure and bolt stress as per Radial Shear Tightness (RAST) Test

- Shell MESC SPE – 85/300 Type Acceptance Test (TAT)

- Fugitive Emissions Test

- Fire Test according to API 6FB

- Compression Test (EN 13555)

- Relaxation Test (EN 13555)

- Leakage Test (EN 13555)

- Hot Operational Tightness Test (HOTT) – Shell Cycle Test

Non-standard Kamprofile gaskets of any size and type can be provided.

Specialty: Heat Exchanger Gaskets as per customer requirement

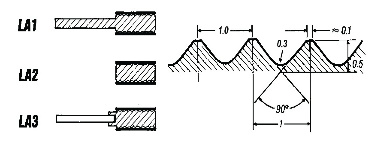

Kamprofile gasket is a composite gasket which utilises a serrated metal core with a soft facing material. The metal core is machined on each contact face with concentric serrations which provide high pressure areas, ensuring that the soft coating flows into any imperfections in the flange even at relatively low bolt loads. The result is a gasket which combines the benefits of soft cut materials with the advantages of seal integrity associated with metallic gaskets.

Expanded graphite is the most common facing material used for Kamprofile gaskets. However, other materials can be used, such as PTFE for chemically aggressive duties or mica for high temperature duties.

|

Facing Material |

Maximum Temperature |

|

Graphite - APX2 |

550ºC |

|

Skived PTFE |

260ºC |

|

Mica |

1000ºC |

|

CNAF – Glass fiber with NBR binder |

250ºC |

Kamprofile gaskets can also be manufactured from a range of core materials according to media compatibility and temperature considerations.

|

Core Material |

Maximum Temperature |

Core Material |

Maximum Temperature |

|

316L Stainless Steel |

800°C |

Inconel 600 |

1000°C |

|

304 Stainless Steel |

650°C |

Inconel 625 |

1000°C |

|

Duplex UN S31803 |

800°C |

Incoloy 825 |

600°C |

|

347 Stainless Steel |

870°C |

Zirconium |

500°C |

|

321 Stainless Steel |

870°C |

Super Duplex |

600°C |

|

Monel 400 |

800°C |

254 SMO |

600°C |

|

Nickel 200 |

600°C |

Titanium Gr7 |

500°C |

|

Titanium Gr 2 |

500°C |

Hastelloy C-22 |

700°C |

|

Hastelloy B-2/B-3 |

700°C |

Hastelloy G-31 |

800°C |

|

Hastelloy C-276 |

700°C |

Alloy 20 |

600°C |

Kamprofile gasket is a composite gasket which utilises a serrated metal core with a soft facing material. The metal core is machined on each contact face with concentric serrations which provide high pressure areas, ensuring that the soft coating flows into any imperfections in the flange even at relatively low bolt loads. The result is a gasket which combines the benefits of soft cut materials with the advantages of seal integrity associated with metallic gaskets.

Expanded graphite is the most common facing material used for Kamprofile gaskets. However, other materials can be used, such as PTFE for chemically aggressive duties or mica for high temperature duties.

|

Facing Material |

Maximum Temperature |

|

Graphite - APX2 |

550ºC |

|

Skived PTFE |

260ºC |

|

Mica |

1000ºC |

|

CNAF – Glass fiber with NBR binder |

250ºC |

Kamprofile gaskets can also be manufactured from a range of core materials according to media compatibility and temperature considerations.

|

Core Material |

Maximum Temperature |

Core Material |

Maximum Temperature |

|

316L Stainless Steel |

800°C |

Inconel 600 |

1000°C |

|

304 Stainless Steel |

650°C |

Inconel 625 |

1000°C |

|

Duplex UN S31803 |

800°C |

Incoloy 825 |

600°C |

|

347 Stainless Steel |

870°C |

Zirconium |

500°C |

|

321 Stainless Steel |

870°C |

Super Duplex |

600°C |

|

Monel 400 |

800°C |

254 SMO |

600°C |

|

Nickel 200 |

600°C |

Titanium Gr7 |

500°C |

|

Titanium Gr 2 |

500°C |

Hastelloy C-22 |

700°C |

|

Hastelloy B-2/B-3 |

700°C |

Hastelloy G-31 |

800°C |

|

Hastelloy C-276 |

700°C |

Alloy 20 |

600°C |