Standard gaskets of all sizes & shape;

Size from ½”to 60”

Pressure class: LBS 150, 300 & 600

Conforming to: ASME: B16.21, B16.47 Series A & B

DIN: PN 10, PN 15, PN 25, PN 32, PN 40, PN 60, PN 65, PN 80, PN 100, PN 125

AWWA: Table C & D

Non-standard gaskets in all sizes, types and shapes

Materials: Rubber products

|

EPDM Applications: Suitable for acid, alkalis and hot water. It is specially suited to hot water, strong alkali applications and KOH Properties: This material has good mechanical properties and is resistant to ageing, weathering, ozone, oxygen, steam and water. Recommended for use where resistance to sunlight, weather, steam and ozone attack is important. Suitable for use with phosphate ester-based hydraulic fluids and many mineral acids. Not suitable for use with petroleum based oils or fluids. Technical Specifications: Colour : Black Density : 1.3 gm/cm³ Hardness (Shore A) : 70º Tensile strength : 3 N/mm² Elongation : 200% Temperature range : -40ºC to +135ºC Availability: In sheet form and cut gasket form with or without insertion. Available in different sizes and thickness. |

NEOPRENE (CR) Applications: Oils, fuels and moderate acids and alkalis, weather and ozone Resistant Properties: Good general purpose polychloroprene sheet recommended for use in less demanding situations with air, water, non-oxidising acid and aliphatic hydrocarbons or where extra resistance to heat, ozone or weathering is required. Technical Specifications: Colour : Black Density : 1.4 gm/cm³ Hardness (Shore A) : 65º Tensile strength : 6 N/mm² Elongation : 300% Temperature range : -10ºC to +90ºC |

|

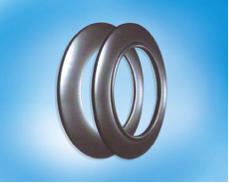

RUBBER STEEL GASKET Standard sizes available from 1/2” to 60” Pressure class : LBS 150, 300 & 600 Conforming to ASME B16.21, B16.47 Series A & B DIN : PN 10, PN 15, PN 25, PN 32, PN 40, PN 60, PN 65, PN 80, PN 100, PN 125 Gasket Material : NR (Natural Rubber), NBR-DUO (Acrylonitrile Butadiene Rubber), HNBR (Hydrogenated Acrylonitrile Butadiene Rubber), CR (Chloroprene Rubber), CSM (Chlorosulphonated Monomer Rubber), EPDM (Ethylene Propylene Diene Monomer Rubber), FPM-S (Fluorinated Rubber Acid Proof, IIR (Isobutene Isoprene Rubber), Steel Insert Standard : Carbon Steel Optional : Stainless Steel Applications : Rubber steel gaskets are suitable for water, steam, gas, air, acids, bases, hydrocarbon etc (depending on their polymer type) while operating temperatures are limited up to 200ºC. The use of rubber steel gasket is recommended especially for applications where only a little surface compression is available. Properties : The steel support ring prevents a blow out of the gasket and increases stability, allowing the rubber-steel gasket to be handled easily, even in difficult fitting conditions. The rubber sealing material ensures a secure seal is created, especially on uneven surfaces, as it has an excellent ability to adapt to sealing surfaces. In conforming to the maximum allowable installation surface pressure. Availability : In the form of Moulded gasket models G-ST-Flange and Profile Gaskets |

|